| 가용성 상태: | |

|---|---|

| 수량: | |

1. 7000mm / 23ft에 대한 안정적이고 정확한 추적.

대부분의 경쟁사를 선도하는 GR8000 시리즈는 높은 수준의 가공에 중요한 기능인 700mm / 23ft에 대한 안정적인 긴 길이 추적을 수행할 수 있다면 대형 사인, 패턴 제작에 이상적입니다.

2. 작은 텍스트 문자열을 정확하게 자릅니다.

최소 0.8MM 원형을 절단할 수 있으며, 폐기물을 쉽게 찢을 수 있습니다.

3. 정전기가 발생하지 않습니다.

부드럽고 얇은 재료를 절단할 때 마찰 정전기 간섭 문제가 해결되었습니다. GR8000 커팅 플로터에서.

4. Adobe Illustrator(AI), CorelDraw, AutoCAD와의 호환성 그리고 더.

명세서

모델 | GR8000-80 | GR8000-140 | GR8000-180 | |

최대. 절단 폭 (비윤곽 절단) | 690mm | 1290mm | 1630mm | |

최대. 절단 폭 (윤곽절단) | 600mm | 1220mm | 1520mm | |

최대. 장착 가능한 미디어 폭 | 840mm | 1440mm | 1780mm | |

최소 장착 가능한 미디어 폭 | 70mm | |||

최대. 절단 속도 | 800mm/초 | |||

최대. 절삭력 | 8단계로 600gf/5.8N | |||

절삭력 설정 | 1gf마다 조정 가능 | |||

운전하다 | 서보 기구 | |||

기계적 분해능 | 0.0125mm | |||

최소 원 직경 | 0.8mm | |||

최소 문자 크기 | 1x1mm | |||

최소 숫자 크기 | 3x3mm | |||

IOS | Win10/8/7/XP | |||

메모리 버퍼 | 2MB | |||

소프트웨어 | Windows 드라이버, SignWork Pro, CAD에서 Plot Pro로 | |||

LCD | 영어/중국어 | |||

파일 형식 | HP-GL,PLT | |||

표준 포트 | USB,RS-232 | |||

등록 표시 감지 | 가르스 | |||

전원 입력 | 90V-240V AC, 50-60Hz | |||

전력 소비 | 60와트 | |||

커터 홀더/펜 홀더 | 각 1개 | |||

커터 블레이드 직경 | 0.9mm, 1.5mm, 2.0mm | |||

커터 블레이드 각도 | 30°,45°,60° | |||

펜의 종류 | 수성섬유팁펜 & 유성볼펜 | |||

재료를 고정하는 방법 | 푸시 롤러 | |||

미디어 스톡 롤러 플레이트 | 포함됨 | |||

바구니 | 옵션의 경우 | |||

GW/NW | 42/27kg | 96/62kg | 105/72kg | |

패키지 크기 LWH | 118x40x57cm (0.27CBM) | 171x40x57cm (0.4CBM) | 220x40x57cm (0.5CBM) | |

1. 7000mm / 23ft에 대한 안정적이고 정확한 추적.

대부분의 경쟁사를 선도하는 GR8000 시리즈는 높은 수준의 가공에 중요한 기능인 700mm / 23ft에 대한 안정적인 긴 길이 추적을 수행할 수 있다면 대형 사인, 패턴 제작에 이상적입니다.

2. 작은 텍스트 문자열을 정확하게 자릅니다.

최소 0.8MM 원형을 절단할 수 있으며, 폐기물을 쉽게 찢을 수 있습니다.

3. 정전기가 발생하지 않습니다.

부드럽고 얇은 재료를 절단할 때 마찰 정전기 간섭 문제가 해결되었습니다. GR8000 커팅 플로터에서.

4. Adobe Illustrator(AI), CorelDraw, AutoCAD와의 호환성 그리고 더.

명세서

모델 | GR8000-80 | GR8000-140 | GR8000-180 | |

최대. 절단 폭 (비윤곽 절단) | 690mm | 1290mm | 1630mm | |

최대. 절단 폭 (윤곽절단) | 600mm | 1220mm | 1520mm | |

최대. 장착 가능한 미디어 폭 | 840mm | 1440mm | 1780mm | |

최소 장착 가능한 미디어 폭 | 70mm | |||

최대. 절단 속도 | 800mm/초 | |||

최대. 절삭력 | 8단계로 600gf/5.8N | |||

절삭력 설정 | 1gf마다 조정 가능 | |||

운전하다 | 서보 기구 | |||

기계적 분해능 | 0.0125mm | |||

최소 원 직경 | 0.8mm | |||

최소 문자 크기 | 1x1mm | |||

최소 숫자 크기 | 3x3mm | |||

IOS | Win10/8/7/XP | |||

메모리 버퍼 | 2MB | |||

소프트웨어 | Windows 드라이버, SignWork Pro, CAD에서 Plot Pro로 | |||

LCD | 영어/중국어 | |||

파일 형식 | HP-GL,PLT | |||

표준 포트 | USB,RS-232 | |||

등록 표시 감지 | 가르스 | |||

전원 입력 | 90V-240V AC, 50-60Hz | |||

전력 소비 | 60와트 | |||

커터 홀더/펜 홀더 | 각 1개 | |||

커터 블레이드 직경 | 0.9mm, 1.5mm, 2.0mm | |||

커터 블레이드 각도 | 30°,45°,60° | |||

펜의 종류 | 수성섬유팁펜 & 유성볼펜 | |||

재료를 고정하는 방법 | 푸시 롤러 | |||

미디어 스톡 롤러 플레이트 | 포함됨 | |||

바구니 | 옵션의 경우 | |||

GW/NW | 42/27kg | 96/62kg | 105/72kg | |

패키지 크기 LWH | 118x40x57cm (0.27CBM) | 171x40x57cm (0.4CBM) | 220x40x57cm (0.5CBM) | |

사진 | 설명 |

정확하고 견고한 푸시 롤러. 우리의 푸시 롤러는 단단한 재료로 만들어져 오랫동안 정확하게 작동할 수 있습니다. 푸시 롤러는 두 가지 압력 수준(강함/낮음)으로 설정할 수 있습니다. 정확하고 견고한 푸시 롤러, 정밀한 재료 공급 롤러 및 고품질 미디어 브래킷 롤러의 조합으로 재료의 안정적인 긴 길이 추적이 보장됩니다. | |

7000mm / 23ft에 대한 안정적이고 정확한 추적. 대부분의 경쟁사를 선도하는 GR8000 시리즈는 높은 수준의 가공에 중요한 기능인 700mm/23ft에 대한 안정적인 긴 길이 추적을 수행할 수 있다면 대형 사인, 패턴 제작에 이상적입니다. | |

고급 도구 캐리지. 공구 캐리지는 기계의 가장 중요한 부분 중 하나입니다. 무소음 보이스 코일 모터로 구동되는 스포츠카 구조를 채택한 GR8000 플로터의 툴 캐리지는 장기간 논스톱 작동을 위해 더 빠르고 더 민첩하며 과열이 없는 것이 특징입니다. | |

흡입 절단 테이블. 조밀한 공기 흡입구와 강력한 공기 흐름으로 미디어를 테이블 상단에 평평하고 단단하게 고정하여 도구 캐리지가 빠르고 정확한 절단/플로팅을 수행할 수 있습니다. | |

서보 모터 / 폐쇄 루프 제어. 도구 캐리지에 과부하가 걸리면 커팅/플로팅이 중지됩니다. 이는 미디어가 걸렸을 때 도구 캐리지를 보호하는 중요한 안전 기능입니다. | |

격자 눈금자. 절단 테이블이나 재료 표면은 지점마다 높이가 동일하지 않을 수 있으므로 정밀 광학 장치인 Gating Ruler를 사용하여 블레이드 끝과 재료 표면 사이의 거리를 실시간으로 측정하고 절단 깊이는 측정된 거리 값에 따라 컨트롤러가 실시간으로 0.01mm 단위로 조정합니다. 그 후, 전체 작업 크기에 걸쳐 해당 도구 경로의 어느 위치에서나 동일한 절단 깊이를 유지하기 위해 재료 표면이 위아래로 이동함에 따라 블레이드가 위아래로 이동합니다. 간단히 말해서 절단 깊이는 일관됩니다. 당신은 다른 색조를 볼 수 없습니다. | |

정전기 제거. 정적 간섭을 완전히 제거하는 것은 PPF 설치자에게 특히 중요합니다. GR8000 시리즈 커터 플로터는 연중 다양한 기상 조건에서 테스트를 거쳐 정적 간섭을 성공적으로 제거했습니다. | |

작은 텍스트를 자릅니다. GR8000 시리즈 비닐 절단기는 고정밀 절단으로 알려져 있으며 Φ0.8mm 크기의 원, 1x1mm 크기의 문자, 3x3mm 크기의 숫자와 같은 작은 텍스트 문자열을 절단할 수 있으며 스크랩을 쉽게 찢을 수 있습니다. | |

품질 구성 요소. 보다 뛰어난 성능과 장기간 안정적인 작동을 위해 BANDO 벨트, MINEBEA 베어링 등과 같은 세계적 수준의 브랜드 부품만을 사용합니다. | |

깨끗한 부드러운 가장자리 품질. 그레이팅 룰러와 상응하는 절삭력 관리는 가장 복잡한 작업에서도 깨끗하고 부드러운 가장자리 품질을 제공합니다. GR8000 시리즈는 작은 텍스트 문자열을 절단할 수 있고 폐기물을 쉽게 떼어낼 수 있어 사용자의 작업량을 크게 줄여줍니다. | |

칩으로 블레이드 팁 보상 만들기. 당사의 시스템은 소프트웨어가 아닌 하드웨어(메인보드)로 블레이드 팁 보상을 수행하므로, 어떤 종류의 CAD/CAM 소프트웨어를 적용하더라도 커터는 일정하고 높은 정밀도로 작동합니다. | |

오프라인일 때 바코드를 스캔하는 중입니다. PC에 연결할 필요 없이 미디어에 인쇄된 바코드를 스캔하여 USB 메모리에 저장된 작업 중에서 원클릭으로 절단 작업을 찾아낼 수 있습니다. 이 기능은 USB 메모리에 많은 파일이 저장되어 있는 경우 생산성을 높이는 데 특히 유용합니다. | |

고급 등록 표시 감지. 등록 표시를 추가하고 개체의 윤곽을 생성하려면 한 번 클릭하세요. 한 번의 클릭으로 등록 표시를 읽고 윤곽 절단을 수행합니다. 절단 경로와 윤곽을 가장 잘 일치시키기 위해 키패드나 소프트웨어를 사용하여 미세 조정이 가능합니다. 재료가 비스듬하게 배치된 경우(15° 이하) 절단기는 여전히 잘 작동할 수 있으며 이 기능은 시간을 절약하는 데 도움이 됩니다. | |

8단계 절삭력s. 당사 소프트웨어 CADtoPlotPro에서 사용자는 다양한 절단 경로에 대해 다양한 색상을 입력하고 처리 순서를 색상 순서로 설정할 수 있으며, 다양한 경로는 다양한 절삭력 단계에 따라 처리됩니다. | |

M다중 레이어 솔루션. 여러 레이어가 있는 미디어의 경우 레이어마다 다른 절삭력이 적용됩니다. | |

가속도: 4000mm/s²/최대. 속도: 800mm/s. 모션 컨트롤러의 고급 알고리즘, 최적화된 공구 경로, X, Y의 서보 모터, Z축의 보이스 코일 모터 및 고품질 정밀 구동 시스템 등 이 모든 요소가 기계를 더 빠르게 움직이고 더 효율적인 처리를 가능하게 합니다. | |

고급 알고리즘. 고급 알고리즘과 고품질 하드웨어를 사용하면 왜곡되거나 둥글거나 들뜬 모서리를 확실히 제거할 수 있습니다. | |

오버컷 필요 없음. 모든 절단 경로에서 시작점과 끝점이 정확하게 일치하며 오버컷이 필요하지 않습니다. | |

하프 컷 / 천공 컷. 하프 컷팅/퍼포레이션 컷팅이 가능하며, 언제든지 둘 중 하나 또는 둘 다를 수행할 수 있습니다. | |

점선 절단. 점선 절단은 일반적으로 2겹의 용지와 종이 종류에 적용 가능합니다. | |

원클릭으로 인쇄 드라이버 설치. 원클릭으로 인쇄 드라이버를 설치하고 USB로 인쇄할 수 있으며, 프린터 기능이 있는 모든 CAD 소프트웨어에서 절단 작업을 보낼 수 있습니다. 당사의 인쇄 드라이버는 Windows 32/64비트에서 작동합니다. | |

DXF 직접 출력. GR8000은 형식 변환이 필요하지 않으며 .DXF 파일과 직접 호환됩니다. | |

한 번의 클릭으로 기록 지우기. 현재 인쇄 중인 문서에 대한 원클릭 삭제 버튼입니다. 작업 파일을 USB 메모리로 전송하고 반복 작업을 지원합니다. | |

최고의 교정. 서로 다른 축 사이의 수직과 갠트리와 절단 테이블 사이의 평행도를 교정하기 위해 업계 최고의 기술이 적용됩니다. | |

AutoCAD, AI, Coreldraw 및 Flexisign과 호환됩니다. 동일한 업계를 선도하는 당사는 자체적으로 소프트웨어를 제작하며, 당사 시스템을 AutoCAD, Adobe Illustrator, Coreldraw 및 Flexisign 등과 같은 널리 사용되는 CAD/CAM 소프트웨어의 최신 버전에 적용할 수 있습니다. | |

핸드셰이크 프로토콜. 우리는 클라이언트의 소프트웨어와 일치하는 소프트웨어 개발 키트/SDK를 공급하여 Gunner와 Professional 클라이언트 간의 협력을 심화합니다. | |

미디어 센서(선택 과목) 미디어의 크기를 측정하는데 적용되며 미디어 크기가 컨텐츠에 비해 충분히 크지 않으면 커팅/플로팅 작업이 수행되지 않으며 컨트롤러는 운영자에게 미디어를 확대하거나 컨텐츠의 크기를 줄이도록 요청합니다. 미디어 센서는 미디어를 절약하고 효율성을 높이는 데 큰 도움이 됩니다. |

사진 | 설명 |

정확하고 견고한 푸시 롤러. 우리의 푸시 롤러는 단단한 재료로 만들어져 오랫동안 정확하게 작동할 수 있습니다. 푸시 롤러는 두 가지 압력 수준(강함/낮음)으로 설정할 수 있습니다. 정확하고 견고한 푸시 롤러, 정밀한 재료 공급 롤러 및 고품질 미디어 브래킷 롤러의 조합으로 재료의 안정적인 긴 길이 추적이 보장됩니다. | |

7000mm / 23ft에 대한 안정적이고 정확한 추적. 대부분의 경쟁사를 선도하는 GR8000 시리즈는 높은 수준의 가공에 중요한 기능인 700mm/23ft에 대한 안정적인 긴 길이 추적을 수행할 수 있다면 대형 사인, 패턴 제작에 이상적입니다. | |

고급 도구 캐리지. 공구 캐리지는 기계의 가장 중요한 부분 중 하나입니다. 무소음 보이스 코일 모터로 구동되는 스포츠카 구조를 채택한 GR8000 플로터의 툴 캐리지는 장기간 논스톱 작동을 위해 더 빠르고 더 민첩하며 과열이 없는 것이 특징입니다. | |

흡입 절단 테이블. 조밀한 공기 흡입구와 강력한 공기 흐름으로 미디어를 테이블 상단에 평평하고 단단하게 고정하여 도구 캐리지가 빠르고 정확한 절단/플로팅을 수행할 수 있습니다. | |

서보 모터 / 폐쇄 루프 제어. 도구 캐리지에 과부하가 걸리면 커팅/플로팅이 중지됩니다. 이는 미디어가 걸렸을 때 도구 캐리지를 보호하는 중요한 안전 기능입니다. | |

격자 눈금자. 절단 테이블이나 재료 표면은 지점마다 높이가 동일하지 않을 수 있으므로 정밀 광학 장치인 Gating Ruler를 사용하여 블레이드 끝과 재료 표면 사이의 거리를 실시간으로 측정하고 절단 깊이는 측정된 거리 값에 따라 컨트롤러가 실시간으로 0.01mm 단위로 조정합니다. 그 후, 전체 작업 크기에 걸쳐 해당 도구 경로의 어느 위치에서나 동일한 절단 깊이를 유지하기 위해 재료 표면이 위아래로 이동함에 따라 블레이드가 위아래로 이동합니다. 간단히 말해서 절단 깊이는 일관됩니다. 당신은 다른 색조를 볼 수 없습니다. | |

정전기 제거. 정적 간섭을 완전히 제거하는 것은 PPF 설치자에게 특히 중요합니다. GR8000 시리즈 커터 플로터는 연중 다양한 기상 조건에서 테스트를 거쳐 정적 간섭을 성공적으로 제거했습니다. | |

작은 텍스트를 자릅니다. GR8000 시리즈 비닐 절단기는 고정밀 절단으로 알려져 있으며 Φ0.8mm 크기의 원, 1x1mm 크기의 문자, 3x3mm 크기의 숫자와 같은 작은 텍스트 문자열을 절단할 수 있으며 스크랩을 쉽게 찢을 수 있습니다. | |

품질 구성 요소. 보다 뛰어난 성능과 장기간 안정적인 작동을 위해 BANDO 벨트, MINEBEA 베어링 등과 같은 세계적 수준의 브랜드 부품만을 사용합니다. | |

깨끗한 부드러운 가장자리 품질. 그레이팅 룰러와 상응하는 절삭력 관리는 가장 복잡한 작업에서도 깨끗하고 부드러운 가장자리 품질을 제공합니다. GR8000 시리즈는 작은 텍스트 문자열을 절단할 수 있고 폐기물을 쉽게 떼어낼 수 있어 사용자의 작업량을 크게 줄여줍니다. | |

칩으로 블레이드 팁 보상 만들기. 당사의 시스템은 소프트웨어가 아닌 하드웨어(메인보드)로 블레이드 팁 보상을 수행하므로, 어떤 종류의 CAD/CAM 소프트웨어를 적용하더라도 커터는 일정하고 높은 정밀도로 작동합니다. | |

오프라인일 때 바코드를 스캔하는 중입니다. PC에 연결할 필요 없이 미디어에 인쇄된 바코드를 스캔하여 USB 메모리에 저장된 작업 중에서 원클릭으로 절단 작업을 찾아낼 수 있습니다. 이 기능은 USB 메모리에 많은 파일이 저장되어 있는 경우 생산성을 높이는 데 특히 유용합니다. | |

고급 등록 표시 감지. 등록 표시를 추가하고 개체의 윤곽을 생성하려면 한 번 클릭하세요. 한 번의 클릭으로 등록 표시를 읽고 윤곽 절단을 수행합니다. 절단 경로와 윤곽을 가장 잘 일치시키기 위해 키패드나 소프트웨어를 사용하여 미세 조정이 가능합니다. 재료가 비스듬하게 배치된 경우(15° 이하) 절단기는 여전히 잘 작동할 수 있으며 이 기능은 시간을 절약하는 데 도움이 됩니다. | |

8단계 절삭력s. 당사 소프트웨어 CADtoPlotPro에서 사용자는 다양한 절단 경로에 대해 다양한 색상을 입력하고 처리 순서를 색상 순서로 설정할 수 있으며, 다양한 경로는 다양한 절삭력 단계에 따라 처리됩니다. | |

M다중 레이어 솔루션. 여러 레이어가 있는 미디어의 경우 레이어마다 다른 절삭력이 적용됩니다. | |

가속도: 4000mm/s²/최대. 속도: 800mm/s. 모션 컨트롤러의 고급 알고리즘, 최적화된 공구 경로, X, Y의 서보 모터, Z축의 보이스 코일 모터 및 고품질 정밀 구동 시스템 등 이 모든 요소가 기계를 더 빠르게 움직이고 더 효율적인 처리를 가능하게 합니다. | |

고급 알고리즘. 고급 알고리즘과 고품질 하드웨어를 사용하면 왜곡되거나 둥글거나 들뜬 모서리를 확실히 제거할 수 있습니다. | |

오버컷 필요 없음. 모든 절단 경로에서 시작점과 끝점이 정확하게 일치하며 오버컷이 필요하지 않습니다. | |

하프 컷 / 천공 컷. 하프 컷팅/퍼포레이션 컷팅이 가능하며, 언제든지 둘 중 하나 또는 둘 다를 수행할 수 있습니다. | |

점선 절단. 점선 절단은 일반적으로 2겹의 용지와 종이 종류에 적용 가능합니다. | |

원클릭으로 인쇄 드라이버 설치. 원클릭으로 인쇄 드라이버를 설치하고 USB로 인쇄할 수 있으며, 프린터 기능이 있는 모든 CAD 소프트웨어에서 절단 작업을 보낼 수 있습니다. 당사의 인쇄 드라이버는 Windows 32/64비트에서 작동합니다. | |

DXF 직접 출력. GR8000은 형식 변환이 필요하지 않으며 .DXF 파일과 직접 호환됩니다. | |

한 번의 클릭으로 기록 지우기. 현재 인쇄 중인 문서에 대한 원클릭 삭제 버튼입니다. 작업 파일을 USB 메모리로 전송하고 반복 작업을 지원합니다. | |

최고의 교정. 서로 다른 축 사이의 수직과 갠트리와 절단 테이블 사이의 평행도를 교정하기 위해 업계 최고의 기술이 적용됩니다. | |

AutoCAD, AI, Coreldraw 및 Flexisign과 호환됩니다. 동일한 업계를 선도하는 당사는 자체적으로 소프트웨어를 제작하며, 당사 시스템을 AutoCAD, Adobe Illustrator, Coreldraw 및 Flexisign 등과 같은 널리 사용되는 CAD/CAM 소프트웨어의 최신 버전에 적용할 수 있습니다. | |

핸드셰이크 프로토콜. 우리는 클라이언트의 소프트웨어와 일치하는 소프트웨어 개발 키트/SDK를 공급하여 Gunner와 Professional 클라이언트 간의 협력을 심화합니다. | |

미디어 센서(선택 과목) 미디어의 크기를 측정하는데 적용되며 미디어 크기가 컨텐츠에 비해 충분히 크지 않으면 커팅/플로팅 작업이 수행되지 않으며 컨트롤러는 운영자에게 미디어를 확대하거나 컨텐츠의 크기를 줄이도록 요청합니다. 미디어 센서는 미디어를 절약하고 효율성을 높이는 데 큰 도움이 됩니다. |

| 파인 블레이드 홀더 이 정밀하게 설계된 구성 요소는 고급 캐리지에 위치하며 선택한 절단 블레이드를 고정합니다. 이 도구는 작업에 필요한 '블레이드 아웃'의 원하는 양을 얻기 위해 수동으로 조정 가능합니다. |

| 교정 도구 절단기를 보정하기 위해 설정 시 사용된 다음 정기적으로 사용됩니다. |

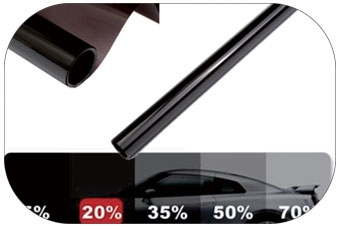

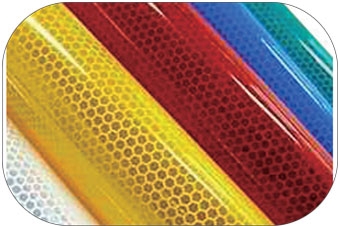

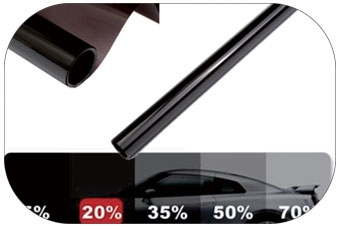

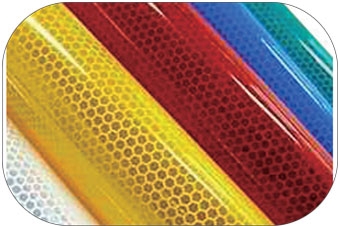

커팅 블레이드 다양한 용도에 맞는 다양한 블레이드를 사용할 수 있습니다. 각도: 두꺼운 용지 또는 작은 문자의 경우 30°/Φ2.0mm. 각도: 반사 필름의 경우 60°/Φ2.0mm. 각도:PPF의 경우 45°/Φ2.0mm. |

| 파인 블레이드 홀더 이 정밀하게 설계된 구성 요소는 고급 캐리지에 위치하며 선택한 절단 블레이드를 고정합니다. 이 도구는 작업에 필요한 '블레이드 아웃'의 원하는 양을 얻기 위해 수동으로 조정 가능합니다. |

| 교정 도구 절단기를 보정하기 위해 설정 시 사용된 다음 정기적으로 사용됩니다. |

커팅 블레이드 다양한 용도에 맞는 다양한 블레이드를 사용할 수 있습니다. 각도: 두꺼운 용지 또는 작은 문자의 경우 30°/Φ2.0mm. 각도: 반사 필름의 경우 60°/Φ2.0mm. 각도:PPF의 경우 45°/Φ2.0mm. |

응용

다양한 인쇄 가능한 자가 접착 재료를 사용할 수 있습니다. 인화지, 티셔츠 전사지, 사진 품질의 잉크젯 카드, 스티커, 광택지, 투명 필름 등

작업 샘플

]=]

응용

다양한 인쇄 가능한 자가 접착 재료를 사용할 수 있습니다. 인화지, 티셔츠 전사지, 사진 품질의 잉크젯 카드, 스티커, 광택지, 투명 필름 등

작업 샘플

]=]